Chain Link Conveyor Belts

Chain Link Conveyor Belt, also known as conventional weave mesh belt, it's the simplest version of universal weave conveyor belt features right and left hand round wires twisted into each other similar to a diamond mesh wire cloth. This design provides large open area to enhance the efficiency of product washing and drying process. Owing to its large open area, Chain Link belt is ideal for light duty use in drying, cooling and heating applications where energy efficiency is the most important.

Chain link conveyor belting consists of interwoven successive spiral wire, which looks like chain link fencing. Different from balanced weave belt consisting of alternating left-hand and right-hand spiral coils, chain link conveyor belting is constructed by unidirectional coils. For a friction driven belt, the belt features alternating sections of left-hand then right-hand. To counteract the tracking issues caused by the unidirectional coil pattern, cross rods are inserted across the belts - one is right-hand woven and the other is left-hand woven.

Advantages

① large opening area, makes it ideal for drying and cooling application where belt flow-through is of paramount importance.

② Simple and functional structure. Successive spiral coils are interwoven to create an open mesh. makes it economical and lightweight than other types of conveyor belt for low load conveying applications.

③ Functional. The stainless steel chain link conveyor belt is suitable for lifting, conveying lightweight products.

④ Baffles are available. Side and center baffles can be added to the conveyor belt. Baffles can prevent the products from falling down to the ground. It is also useful for sorting and conveying.

Applications

Chain Link belting is the simplest available wire belt design, suitable for light duty use in drying and cooling applications. Chain Link is a component part of Troughing Filter Belts, and can also be used as collapsible screen for applications such as lift guards.

|

● Transport light-duty products ● Cooling ● Drying ● Heating ● Drainage ● Industrial Curtains ● Lift Guards ● Elevating ● De-Elevating ● Metal working industry |

● Annealing furnaces ● Cleaning machines ● Conveyor machines ● Drying ovens ● Frosters ● Frying machine ● Ovens ● Refrigeration facilities ● Wrapping machines. ● Serving as metallic screen at lifting platforms. ● Industrial Furnaces |

Belt Types

|

|

|

|

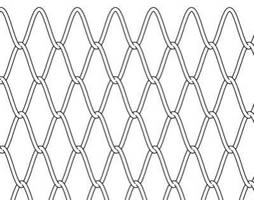

CLCB01 - Standard Chain Link Belt |

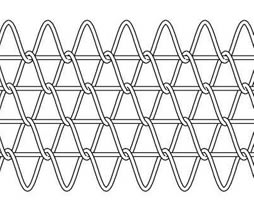

CLCB02 - Rod Reinforced Chain Link Belt |

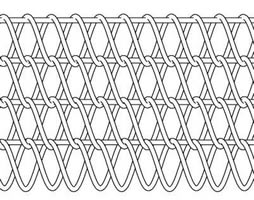

CLCB03 - Rod Reinforced Chain Link Belt - Duplex |

|

|

|

|

Edge Availability

Materials Availability

Specifications

Advantages

Hebei Risen Conveyor Belt Products Co., Ltd

Hebei Risen Conveyor Belt Products Co., Ltd