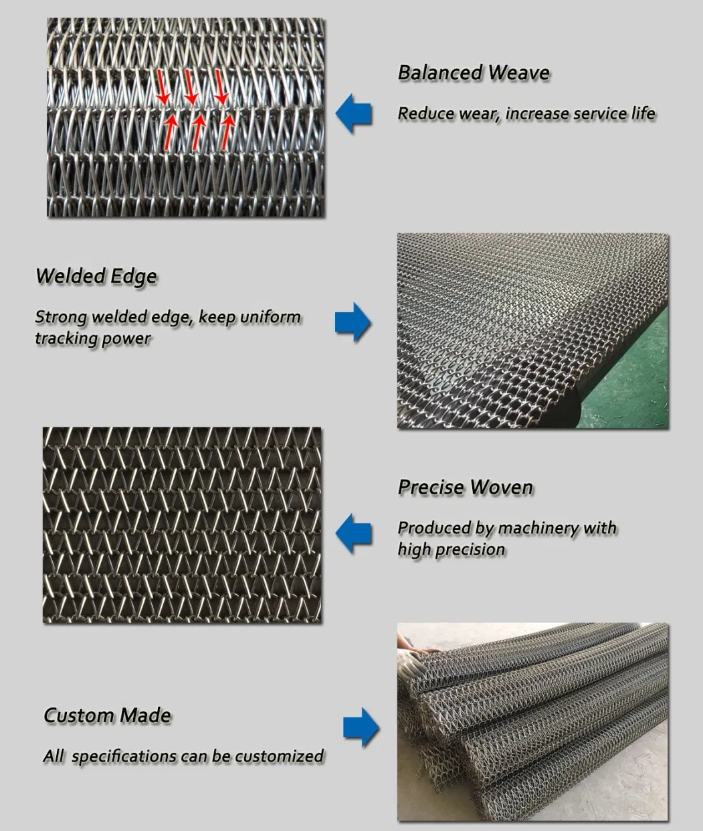

Balanced Spiral Conveyor Belts

Materials Available

|

Material |

Maximum Wire Operating Temperature °C |

|

Carbon Steel(40/45) |

550 |

|

Galvanized Mild Steel |

400 |

|

Chrome Molybdenum(3% Chrome) |

700 |

|

304 Stainless Steel(1.4301) |

750 |

|

321 Stainless Steel(1.4541) |

750 |

|

316 Stainless Steel(1.4401) |

800 |

|

316L Stainless Steel(1.4404) |

800 |

|

314 Stainless Steel(1.4841) |

1120 |

|

37/18 Nickel Chrome(1.4864) |

1120 |

|

80/20 Nickel Chrome(2.4869) |

1150 |

|

Inconel 600(2.4816) |

1150 |

|

Inconel 601(2.4851) |

1150 |

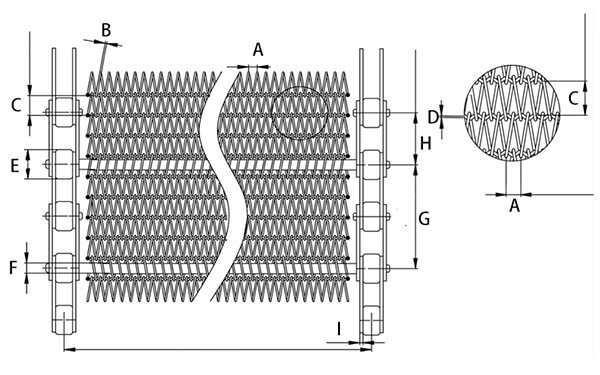

Specifications

|

A: Spiral Wire Pitch (mm) B: Spiral Wire Diameter (mm) C: Cross Rod Pitch (mm) D: Cross Wire Diameter (mm) E: Roller Diameter (mm) F: Cross Rod Diameter (mm) G: Cross Rod Pitch (mm) H: Chain Pitch (mm) I: Plate Thickness (mm) |

|

Balanced Weave Conveyor Belts Specifications |

||||

|

Item No. |

Spiral wire pitch |

Cross rod pitch |

Spiral wire diameter |

Cross wire diameter |

|

mm |

mm |

mm |

mm |

|

|

BWCB-001 |

4 |

4 |

0.9 to 1.2 |

1.2 to 1.6 |

|

BWCB-002 |

5 |

6.4 |

0.9 to 1.2 |

1.2 to 1.6 |

|

BWCB-003 |

5 |

5 |

0.9 to 1.6 |

1.2 to 1.6 |

|

BWCB-004 |

6 |

6 |

0.9 to 1.6 |

1.2 to 1.6 |

|

BWCB-005 |

6 |

8 |

0.9 to 1.2 |

1.2 to 1.6 |

|

BWCB-006 |

6 |

10 |

0.9 to 1.6 |

1.2 to 1.6 |

|

BWCB-007 |

8 |

12 |

1.2 to 2.0 |

1.2 to 2.5 |

|

BWCB-008 |

8 |

13 |

1.2 to 2.0 |

1.2 to 2.5 |

|

BWCB-009 |

8 |

15 |

1.2 to 2.0 |

1.2 to 2.5 |

|

BWCB-010 |

11 |

15 |

1.2 to 2.0 |

1.2 to 2.5 |

|

BWCB-011 |

11 |

20 |

1.6 to 3.0 |

1.6 to 3.0 |

|

BWCB-012 |

11 |

25 |

1.6 to 3.0 |

1.6 to 3.0 |

|

BWCB-013 |

11 |

27 |

1.6 to 3.0 |

1.6 to 3.0 |

|

BWCB-014 |

15 |

20 |

1.6 to 3.0 |

1.6 to 3.0 |

|

BWCB-015 |

15 |

25 |

1.6 to 3.0 |

1.6 to 3.0 |

|

BWCB-016 |

22 |

23 |

1.6 to 3.0 |

1.6 to 3.0 |

|

BWCB-017 |

22 |

33 |

1.6 to 3.0 |

2.0 to 4.0 |

|

*Note: 1. If flat wire, please give us cross section. 2. Custom specification is available if you can't find the suitable size. |

||||

Belt Types

Balance weave conveyor belts are available in various pitches, wire diameters, mesh lengths for numerous applications whether it be heavy loads conveying by super strong belts or transporting small or unsorted products by conveyor belts with high density. The opening of balanced weave belts is determined by pitches of spirals and cross rods which range from 4mm up to 50mm. Additionally, spirals wires can be executed with round and flat wires to suit your needs. Here are seven main styles of balanced weave conveyor belts as shown in following pictures:

|

|

| BWB01-Standard Balanced Spiral Woven Belt | BWB02-Double Balanced Spiral Woven Belt |

|

|

| BWB03-Standard balanced Spiral Woven Belt with straight cross wire | BWB04-Double Balanced Spiral Woven Belt with straight cross wire |

|

|

|

|

BWB05-Standard balanced conveyor belt with flat spiral wire |

BWB06-Flat coil wire balanced weave belt straight cross rod |

BWB-07 Double coil wire balanced weave conveyor belt |

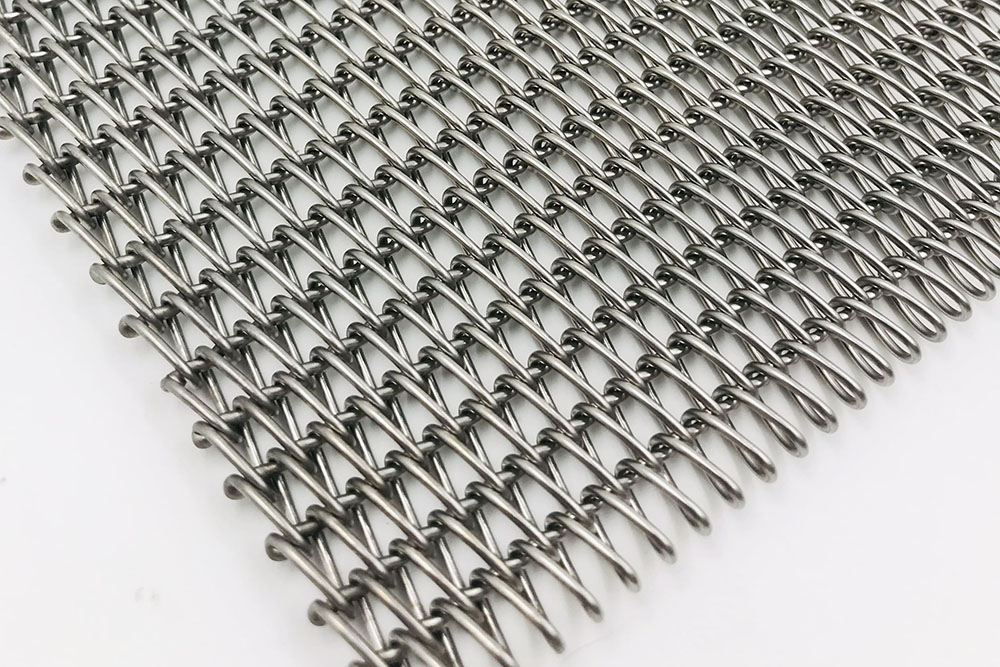

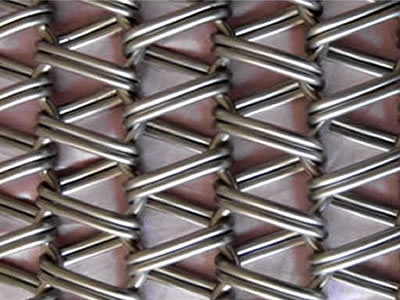

BWB01-Standard Balanced Spiral Woven Belt

This wire belt consists of single alternating left and right-hand spiral coils connecting by a crimped cross wire.

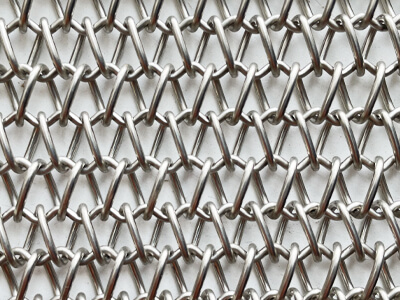

BWB02-Double Balanced Spiral Woven Belt

It uses alternating double left-hand and right-hand spiral coils connected by a crimped cross rod. This kind mesh belt allows for carrying heavy-load small products at elevated temperature.

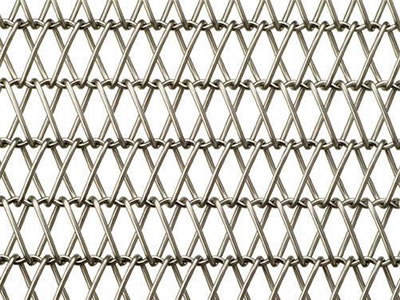

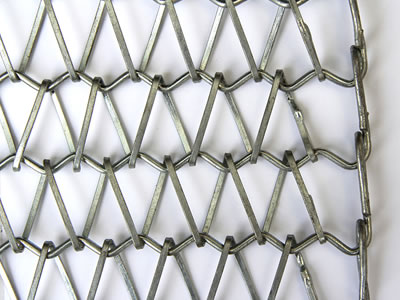

BWB03-Standard balanced Spiral Woven Belt with straight cross wire

The structure uses a straight cross wire with single interconnecting coils in a repeat pattern of left hand/right hand down the length.

BWB04-Double Balanced Spiral Woven Belt with straight cross wire

The structure of this belt is similar to “Double Balanced Spiral” but uses a straight cross wirewith double intermeshing coils of each handing interconnecting by means of the straight cross wire in a repeat pattern of left hand/right hand coils down the length. This assembly allows for a closer pitching of coils across the width for small product handling.

BWB05-Standard balanced conveyor belt with flat spiral wire

Flat coil wire is frequently used for more stable carrying surface. Flat wire interconnects by crimped cross rods.

BWB06-Flat coil wire balanced weave belt straight cross rod

Flat coil wire is frequently used for more stable carrying surface. Flat wire interconnects by straight cross rods.

BWB-07 Double coil wire balanced weave belt

Double coil wires interconnecting by crimped cross rods are available on request. It is designed for carrying heavier products.

Edge Available

To extend the lifespan of balanced weave conveyor belt and ensure the high efficient working and conveying, we can supply different edge types for your choice. The main types of balanced weave conveyor belts are as follows:

|

|

|

BWB-08: Welded edge |

BWB-09: Laddered edge |

|

This is the most popular and economical edge finish. Both spiral coils and crimp cross wire are welded together without cut wire ends.------------------------------------------------------ |

This is less popular than the welded edge finish, but also an option. This edge finish is also smooth and flexible, it is available for conveyor mesh with a relatively large cross wire pitch. |

|

|

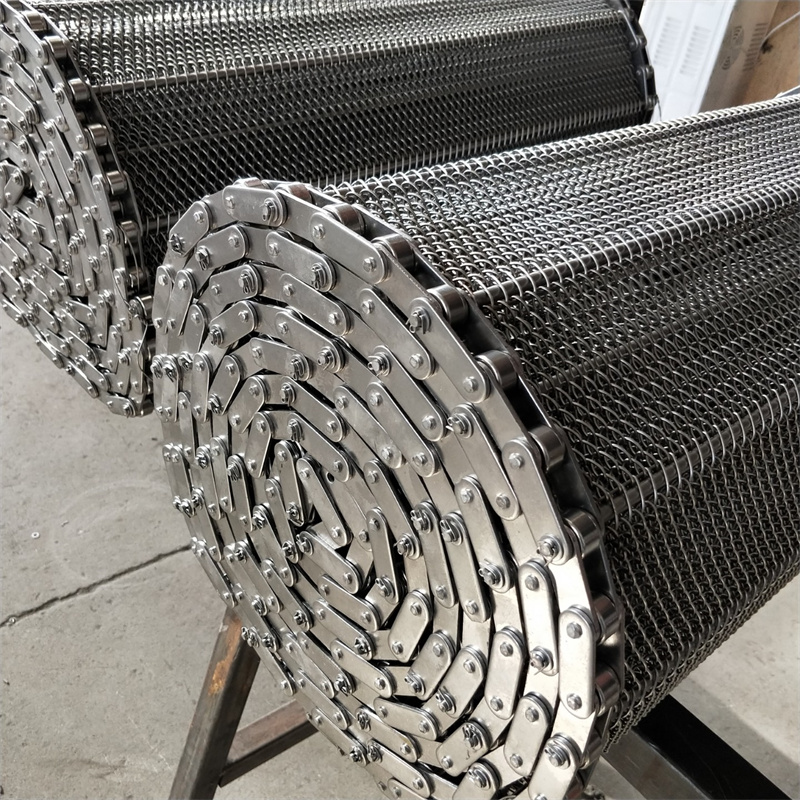

| BWB-10: Hook edge | BWB-11: Chain edge |

|

It is also less common than the welded edge, also an option for the applications where welded edge finish is not possible. It is the better choice for high temperature applications. Similar to hook edge, it is also available for mesh with large cross wire pitch. |

Along with the above mesh edge finishes these meshes can be driven by side chains using cross rods which are located through the mesh coils and then through chains at the edges of the mesh. -------------------------------------------------------------------------------------- |

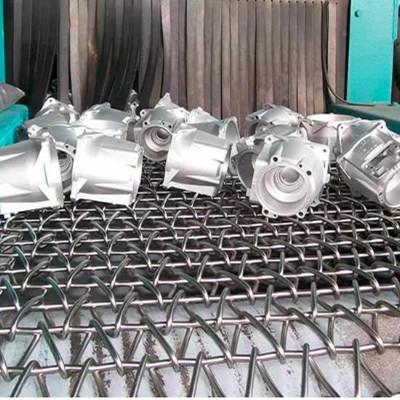

Applications

Balanced spiral conveyor belts are the most versatile and widely used metal conveyor belts, as their good flexibility, excellent strength-to-weight ratio, flat surface and minimal maintenance. This kind belt is typically friction driven and are often used to convey a variety of products, especially those that are small or require a lot of support. Food processing spiral wire chain conveyor belts are often used for product conveying and baking applications. Balanced spiral belts can also be used in industrial product processing, transfer and packaging applications.

|

|

|

Ÿ Vegetable cleaning machinery, sorting, sterilization, quick freezing, Biscuit oven, cooler, fuel injector, salt spreader, etc.

Ÿ Industrial Product Processing, Transfer and Packaging Belts

Ÿ Annealing Oven Conveyor Belts

Ÿ Cooker and Fryer Conveyor Belts

Ÿ Drying and Cooling Conveyor Belts

|

|

|

Advantages

Ÿ Various materials for choice.

Ÿ High temperature resistance.

Ÿ Corrosion and rust resistance.

Ÿ Quick and easy install and replacement.

Ÿ Low maintenance cost.

Ÿ Curved balanced weave conveyor belt to suit more equipment.

Ÿ Side guard can be added onto balanced weave conveyor belt to prevent products from falling down to the ground.

Support & Help Info

For now, wire mesh conveyor belt is mainly divided into major categories: Chain Driven Mesh Belt is widely used in spiral freezer machines; Spiral Mesh Belts are suitable for the conveying of small and high density materials; Eye Link Belt is suited to convey heavy loads and unstable or fragile products that require good support from the conveyor belt; Balanced Weave Belt is extensively applied for conveying parts of metallurgy, food processing, pharmacy, glass print, special equipments; Flat flex belt is mainly used in for quick-frozen food, fried food, sugar machine, chocolate coating with a variety of bread and pastry food baking conveyor line; Flat Wire Belt is usually used for the equipment of cooling, drying, bread production, washing, sorting and products processing, etc. In a word, according to the use environment and clients’ special requirements, we can be able to give them different type of conveyor belt.

For all of your conveyor belt installation, commissioning, condition monitoring, and maintenance, please rest assured to contact us today!

---

---  ---

---

Hebei Risen Conveyor Belt Products Co., Ltd

Hebei Risen Conveyor Belt Products Co., Ltd