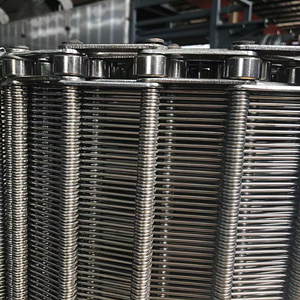

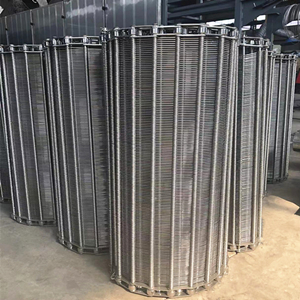

Eye Link Conveyor Belts

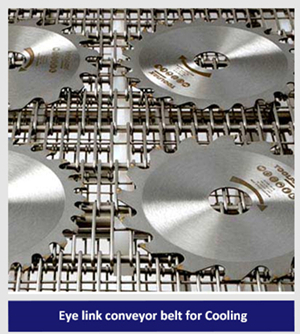

Eye link conveyor belt also known as wire loop conveyor belt, is a type of conveyor belt that is made of interlocking metal links. These links are connected together in a lattice pattern to form a continuous belt. The unique design of the eye link conveyor belt allows for good air circulation and drainage, making it suitable for applications where product cooling or drying is required.

The metal links of eye link belts are typically made of stainless steel, which makes the belt resistant to corrosion, high temperatures and heavy loads, makes it an ideal choice for industries such as food processing, automotive and manufacturing where hygiene, durability and reliability are important.

In addition, eye-link conveyor belts offer smooth and quiet operation, reducing noise levels in the workplace. They can handle a wide range of products, from small components to large, heavy items, making them a versatile solution for various industries.

|

|

Advantages

① High Load Capacity: The high load-bearing capacity of Eye link Belt enables the transportation of heavier materials with ease, enhancing overall operational efficiency.

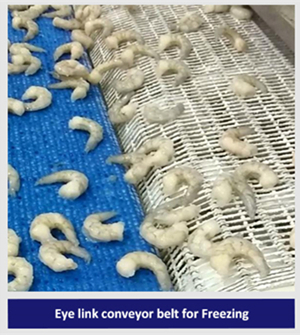

② Flat Carrying Surface: Smooth surface of eye link belt minimizes product abrasion during transportation and prevents product sticking, optimizing freezing efficiency.

③ Durability: Made from stainless steel, eye link conveyor belt offers resistance to wear, tear, and corrosion, extending its lifespan, ensuring hygienic freezing processes.

④ Easy Maintenance: Open eye link structure allows for effortless cleaning and prevents food particles from getting trapped, educing downtime, maximizing productivity.

⑤ Customizability: Eyelink belt can be tailor-made: width,length,open area and pitch to meet unique requirements of particular application, ensuring optimal performance.

Applications

Eye Flex steel conveyor belt is often used in food processing for its flat conveying surface, open mesh configuration, and ease of cleaning. Eyelink conveyor belts stability and robustness of metal and are well suited to convey heavy loads and unstable or fragile products that require good support from the conveyor belt. Eyelink metal conveyor belts find applications in a wide range of industries, including but not limited to:

|

|

|

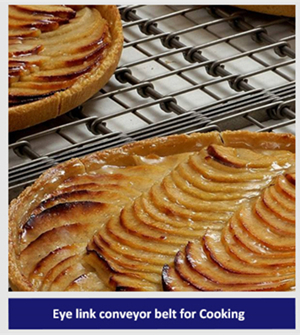

① Food Processing Industry: Ideal for product conveying, washing, drying, cooling, baking, frying, cooling, and freezing.

② Automotive Industry: Used in automotive parts painting, cleaning, and curing processes, Robust and reliable conveying solution for automobile manufacturing.

③ Packaging Industry: Supports efficient packaging(bottles, cans, boxes) and material handling in industries like logistics, cosmetics and consumer goods.

④ Glass Manufacturing: Facilitates the transportation of fragile glass sheets or bottles during the production process.

⑤ Electronics Industry: Handling delicate electronic components during assembly, Suitable for circuit board production, component handling and washing processes.

⑥ Pharmaceutical Industry: Eye link conveyor belt meets the stringent cleanliness requirements of pharmaceutical manufacturers, making it perfect for washing vials, syringes, and other medical equipment, Ideal for pharmaceutical companies requiring rapid freezing of medications and biomedical products.

|

|

|

- Material: SS 304, SS 316, carbon steel

- Wire diameter: 1.5 mm, 1.6 mm, 1.8 mm, 2 mm, 2.5 mm, 3 mm.

- Spiral pitch: 2.4 mm to 100 mm.

- Rod pitch: 25.4 mm, 31.75 mm, 38.1 mm, 50.8 mm, 63.5 mm, 76.2 mm.

- Chain pitch: 25.4 mm, 31.75 mm, 38.1 mm, 50.8 mm, 63.5 mm, 76.2 mm.

- Rod diameter: 5 mm, 6 mm, 7 mm, 8 mm, 10 mm, 12 mm.

- Belt width: 200 mm to 6,000 mm.

|

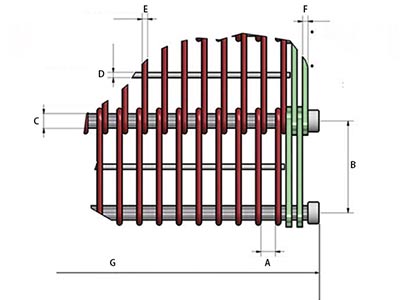

A: Gap Width (mm) D: Underside Welded Wire Dia (mm)

E: Wire Link Dia (mm) G: Overall Belt Width (mm) |

|

Table 1 - Eyelinks conveyor belt without spacers |

||||||

|

Item No. |

Belt Pitch (mm) |

Wire Dia. (mm) |

Cross Rod Dia.(mm) |

Belt Pitch (mm) |

Wire Dia. (mm) |

Cross Rod Dia.(mm) |

|

RSELCB01 |

15.875 |

1.8 |

3.2 |

50 |

3 |

5 |

|

RSELCB02 |

25 |

2 |

5 |

50.8 |

1.6 |

8 |

|

RSELCB03 |

25.4 |

2 |

5 |

50.8 |

1.6 |

6 |

|

RSELCB04 |

30 |

1.6 |

4 |

50.8 |

2 |

8 |

|

RSELCB05 |

30 |

2 |

4 |

50.8 |

2.5 |

8 |

|

RSELCB06 |

30 |

2 |

5 |

50.8 |

2.5 |

5 |

|

RSELCB07 |

30 |

2 |

7 |

50.8 |

3 |

5 |

|

RSELCB08 |

30 |

2 |

8 |

50.8 |

4 |

7 |

|

RSELCB09 |

31.75 |

2 |

5 |

60 |

2 |

5 |

|

RSELCB10 |

50 |

1.4 |

5 |

60 |

2.5 |

5 |

|

RSELCB11 |

50 |

1.6 |

5 |

70 |

4 |

7 |

|

RSELCB12 |

50 |

2 |

5 |

75 |

2.5 |

5 |

|

RSELCB13 |

50 |

2.5 |

6 |

75 |

2.5 |

8 |

|

RSELCB14 |

50 |

2.5 |

8 |

100 |

3 |

8 |

|

Table 2 - Eye link conveyor belt with under welded wire spacing |

||||||

|

Item No. |

Belt Pitch |

Wire Diameter |

Cross Rod Diameter |

Minimum Gap |

Gap in Steps of |

Maximum No. of Welded Wires |

|

RSECBWS01 |

15.875 |

1.8 |

3.2 |

2 |

0.1 |

1 |

|

RSECBWS02 |

25 |

2 |

5 |

2.3 |

0.1 |

2 |

|

RSECBWS03 |

25.4 |

2 |

5 |

2.3 |

0.1 |

2 |

|

RSECBWS04 |

30 |

2 |

4 |

2.3 |

0.1 |

2 |

|

RSECBWS05 |

30 |

2 |

5 |

2.3 |

0.1 |

2 |

|

RSECBWS06 |

50 |

2 |

5 |

2.3 |

0.1 |

3 |

|

RSECBWS07 |

50 |

2.5 |

5 |

2.8 |

0.1 |

3 |

|

RSECBWS08 |

50 |

2.5 |

6 |

2.8 |

0.1 |

3 |

|

RSECBWS09 |

50.8 |

2.5 |

8 |

2.8 |

0.1 |

3 |

|

RSECBWS10 |

50.8 |

3 |

8 |

3.3 |

0.1 |

3 |

|

RSECBWS11 |

75 |

2.5 |

5 |

2.8 |

0.1 |

3 |

|

RSECBWS12 |

75 |

2.5 |

8 |

2.8 |

0.1 |

3 |

|

Table 3 - Eye link conveyor belt with rings as spacers |

|||||

|

Item No. |

Belt Pitch (mm) |

Wire Diameter (mm) |

Cross Rod Diameter (mm) |

Minimum Gap Spacing (mm) |

Gap Spacing can be |

|

RSECBWR01 |

25 |

2 |

5 |

4 |

2 |

|

RSECBWR02 |

25.4 |

2 |

5 |

4 |

2 |

|

RSECBWR03 |

30 |

2 |

4 |

4 |

2 |

|

RSECBWR04 |

30 |

2 |

5 |

4 |

2 |

|

RSECBWR05 |

31.75 |

2 |

5 |

4 |

2 |

|

RSECBWR06 |

50 |

2 |

5 |

4 |

2 |

|

RSECBWR07 |

50 |

2.5 |

5 |

5 |

2.5 |

|

RSECBWR08 |

50 |

2.5 |

6 |

5 |

2.5 |

|

RSECBWR09 |

50.8 |

2.5 |

6 |

5 |

2.5 |

|

RSECBWR10 |

50.8 |

2.5 |

8 |

5 |

2.5 |

|

RSECBWR11 |

50.8 |

4 |

8 |

8 |

4 |

|

RSECBWR12 |

60 |

2 |

5 |

4 |

2 |

|

RSECBWR13 |

60 |

2.5 |

5 |

5 |

2.5 |

|

RSECBWR14 |

75 |

2.5 |

5 |

5 |

2.5 |

|

RSECBWR15 |

75 |

2.5 |

8 |

5 |

2.5 |

|

Table 4 - Eye link conveyor belt with springs as spacers |

||||||||||

|

Item No. |

Belt Pitch |

Wire Diameter |

Cross Rod Diameter |

Minimum Gap Spacing |

Gap Spacing also Available in these Widths (mm) |

|||||

|

RSECBWS01 |

25 |

2 |

5 |

7 |

8 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS02 |

25.4 |

2 |

5 |

7 |

8 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS03 |

30 |

2 |

4 |

7 |

8 |

10 |

12 |

- |

- |

20 |

|

RSECBWS04 |

30 |

2 |

5 |

7 |

8 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS05 |

31.75 |

2 |

5 |

7 |

8 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS06 |

50 |

2 |

5 |

7 |

8 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS07 |

50 |

2.5 |

5 |

7.5 |

8 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS08 |

50 |

2.5 |

6 |

7.5 |

- |

- |

- |

- |

- |

20 |

|

RSECBWS09 |

50 |

3 |

8 |

10.5 |

- |

- |

- |

15.5 |

- |

20 |

|

RSECBWS10 |

50.8 |

2 |

6 |

7 |

- |

- |

- |

- |

- |

- |

|

RSECBWS11 |

50.8 |

2 |

8 |

8 |

- |

- |

- |

- |

- |

- |

|

RSECBWS12 |

50.8 |

2.5 |

6 |

7.5 |

- |

- |

- |

- |

- |

20 |

|

RSECBWS13 |

50.8 |

2.5 |

8 |

10 |

- |

- |

- |

15 |

- |

20 |

|

RSECBWS14 |

50.8 |

3 |

8 |

10.5 |

- |

- |

- |

15.5 |

- |

20 |

|

RSECBWS15 |

50.8 |

4 |

8 |

12 |

- |

- |

- |

- |

- |

- |

|

RSECBWS16 |

60 |

2.5 |

5 |

7 |

8 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS17 |

60 |

2.5 |

5 |

7.5 |

8.5 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS18 |

70 |

4 |

7 |

12 |

- |

- |

- |

- |

- |

- |

|

RSECBWS19 |

75 |

2.5 |

5 |

7.5 |

8.5 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS20 |

75 |

2.5 |

8 |

10 |

- |

10 |

- |

15 |

- |

20 |

|

RSECBWS21 |

100 |

3 |

8 |

10.5 |

- |

10.5 |

- |

15.5 |

- |

20 |

Materials Available

For the production of Eye Link Wire Mesh Conveyor Belts, we could choose: 304 & 316 stainless steel, Carbon steel and other materials.

|

Material |

Maximum Wire Operating Temperature °C |

Feature |

|

Carbon Steel |

550 |

Good wearability |

|

Stainless Steel 304 |

750 |

Often used |

|

Stainless Steel 316 |

850 |

Corrosion-resistant |

Belt Types

|

|

|

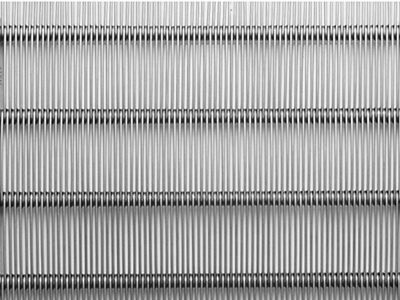

ELCB01 - Eye Link Conveyor Belt without spacers |

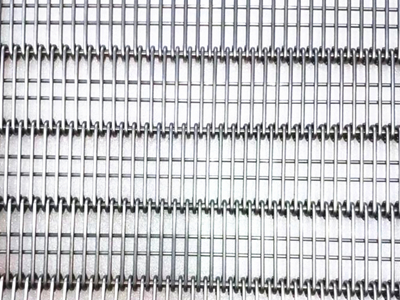

ELCB02 - Eye Link Conveyor Belt with welded wire |

ELCB01 - Eye Link Conveyor Belt without spacers:

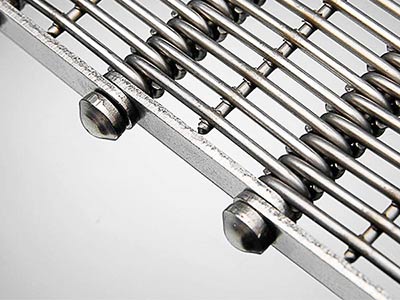

ELCB03 - Eye Link Conveyor Belt with rings as spacers

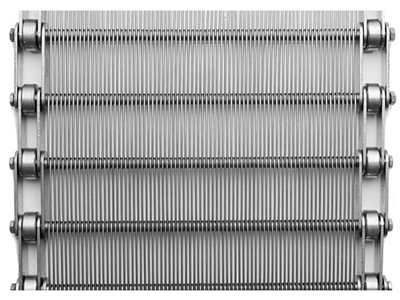

ELCB04 - Eye Link Conveyor Belt with springs as spacers

ELCB05 - Eye link Conveyor Belt with bushings or washers

Eye Link Conveyor Belts without spacers are standard conveyor belts with the simplest structure based on a straight modular form without any spacers and springs, which makes it excellent flow-through in applications that do not require cross support. Eye Link Conveyor Belt has flat conveying surface and open mesh structure, which make it ease of cleaning, also easy to repair at the lowest cost.

ELCB02 - Eye Link Conveyor Belt with welded wire:

Eye link belt has steel wires which was welded under the belt, this not only enhances the stability of the belt, but also prevents bacteria from being left behind due to gaps in the belt. Eye link Conveyor Belt with welded wire is very suitable for applications with high hygiene requirements, such as the processing of various meats and the cleaning and drying of vegetables and fruits.

ELCB03 - Eye Link Conveyor Belt with rings as spacers:

The conveyor belt uses rings as spacers to expand the belt gap and increase more air flow at the bottom of the conveyed product, thereby improving the working efficiency of the conveyor belt. This type of conveyor belt is commonly used for large product conveying, vegetable blanching, container pasteurization, and food cooking, baking, and cooling.

ELCB04 - Eye Link Conveyor Belt with springs as spacers:

Adding springs between eye-link wires, the springs make the eye-link wires able to move on the cross rods, which make the belt form a more dimensionally stable structure. The addition of springs increases the belt open area, which is more conducive to the cleaning and disinfection of the conveyor belt. This belt usually used for product transportation, vegetable blanching, and pasteurization of cans, bottles, and cans.

ELCB05 - Eye link Conveyor Belt with bushings or washers:

Eye link belt uses bushings or washers between the wires to increase the belt gap, create an opening between the eyelinks. By increasing the belt gap, more air will circulate around the bottom of the product. In addition, the belts become heavier and more rigid after bushings or washers are added.

Edge Types

There are four edge types of the Eye link wire mesh belting as following:

|

|

| ELBE01 - Eyelink Belt with Welded edge |

ELBE02 - Eyelink Belt with Reinforcing Plates |

|

---------Eye link belt with welded edge is the simplest eyelink belt edge, through welding metal plates to cross rod at the edge of the wire ring conveyor belt, to form a complete conveyor belt . |

Reinforcing plates are common edge, through adding reinforcing plates mounted to the conveyor belt edge before the connecting rod is welded to further enhance the width and strength of this belt. |

|

|

|

ELBE03 - Eyelink Belt with Chain Edge |

ELBE04 - Eyelink Belt with side Guards |

|

Chain edges on Eye link belts as an alternative method for driving the belt for enhanced tracking and reliability, make the chain edge conveyor belt much stronger than reinforcing plate edge. |

Eye Link belts with side guards can efficientlly protect conveying products from falling off the side of the belt. As your request, guard plates can also be mounted across the belt for food separation. |

Support & Help Info

The Eyelink Metal Conveyor Belt sets a new industry standard with its exceptional build quality, customization options, and versatile applicability. By investing in this innovative conveyor belt, businesses can optimize efficiency, reduce production downtime, and ensure consistent material handling. Overall, wire link conveyor belts are a durable, reliable, and efficient solution for material handling in a wide range of industries. Their unique design and high-quality construction make them an ideal choice for applications that require robust and hygienic conveyor systems.

For all of your wire ring belt installation, commissioning, condition monitoring, and maintenance, please rest assured to contact us today!

Click Here To Watch Product Video

Request a Quote

Hebei Risen Conveyor Belt Products Co., Ltd

Hebei Risen Conveyor Belt Products Co., Ltd