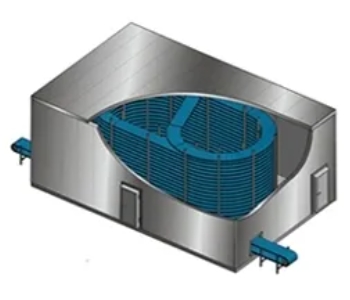

Spiral Cooling Tower

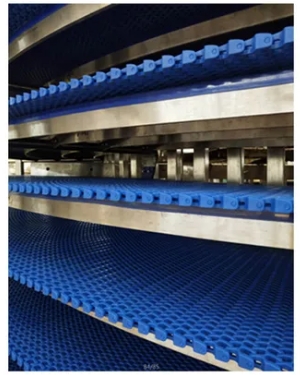

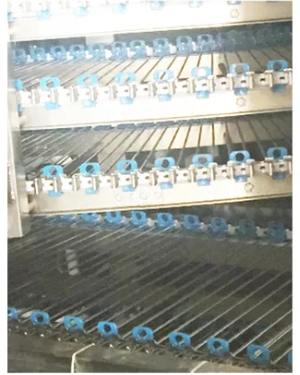

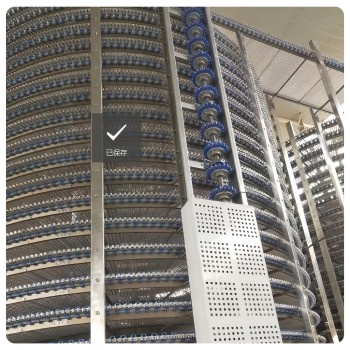

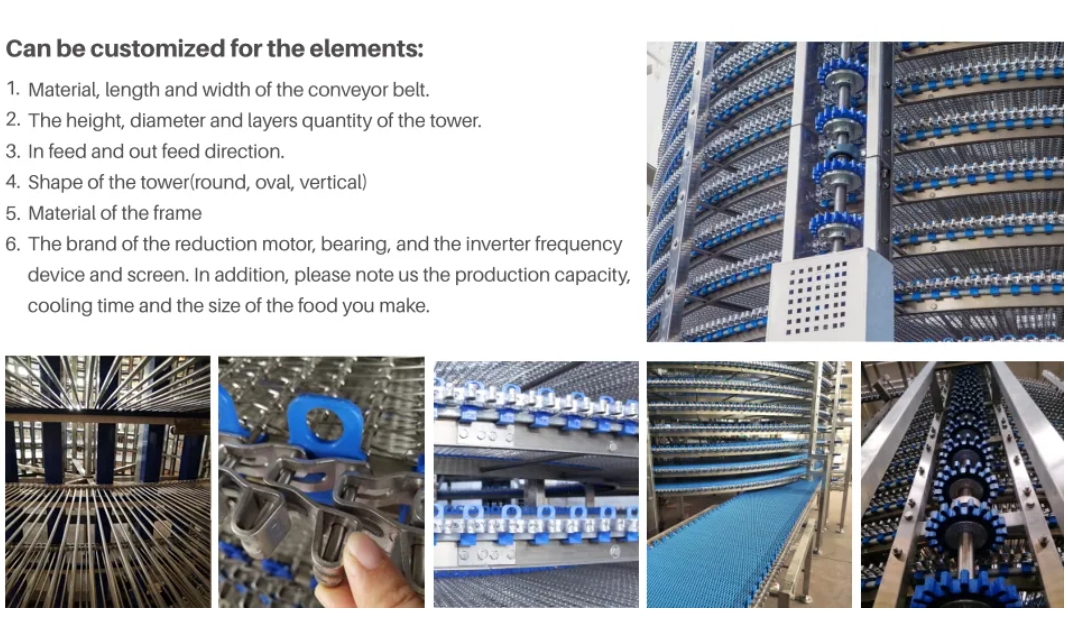

Spiral Cooling Tower is mainly used for cooling products in the baking industry. Baked products are output from the tunnel furnace and enter the spiral cooling tower for natural air cooling or forced cooling. The main applicable products include toast, hamburgers, croissants, biscuits, pizza and other similar products.The conveyor belt has a variety of specifications and materials to choose from, generally using food-grade stainless steel 304 and food-grade PP, POM plastic. Mesh belt width 200-1300 mm; distance between layers and layer numbers in accordance with the capacity; cooling time 20-120 min. We can design a spiral cooling equipment suitable for you according to your product type, production requirements, site conditions, etc.

|

|

|

|

Stalinless Steel Belt |

Plastic Belt |

Stalinless Steel Rod Belt |

Characteristics of Spiral Cooling Tower:

1. With a large single machine capacity, it can achieve fully automatic continuous and large-scale production, greatly improving production efficiency;

2. Maximizing the use of space advantages, occupying a small area, greatly saving users' site investment costs;

3. The width, interlayer spacing, and number of layers of the spiral mesh belt can be customized according to the production volume. The positions of the product enter and come out can be changed in direction according to user requirements. The product can enter from the top and come out from the bottom or enter from the bottom and come out from the top or enter from the bottom and come out also from the bottom. The best solution can be designed according to the actual site requirements of the user;

4. The entire process is controlled by computer automation, with frequency conversion to adjust the running speed of the mesh belt. The cooling time can be infinitely adjusted according to the needs of different products;

5. At the same time, the spiral mesh belt automatic cleaning and drying device designed and manufactured by our company is available for users to choose from.

|

|

|

Application of Spiral Tower in Baking and Cold Mix Food Production Process:

1. Spiral cooling tower: As a cooling equipment in baking production lines, it is applied to the cooling of baked goods such as bread, hamburgers, toast, cakes, mooncakes, etc. in the later stage after baking. Its compact structural design and good cooling effect perfectly reflect the significant superior performance of the spiral tower in its application process;

2. Spiral hair awakening room: as an important equipment in the process of baking and cold food processing and production, the spiral tower is used in the hair awakening process of dough, steamed buns, Mantou and other food production processes through the addition of thermal insulation, special temperature and humidity air conditioning box for hair awakening, air supply and return system and multi-point control of the temperature and humidity inside the machine, which can achieve full automatic and continuous production, and hair awakening is more uniform, which greatly reduces the labor intensity and reduces the operating costs for enterprises.

3. Spiral freezer: Used for rapid freezing of food, spiral freezer is also the best freezer equipment today.

|

|

|

|

Spiral Proofing Tower |

Spiral Cooling Tower |

Spiral Freezing Tower |

Hebei Risen Conveyor Belt Products Co., Ltd

Hebei Risen Conveyor Belt Products Co., Ltd