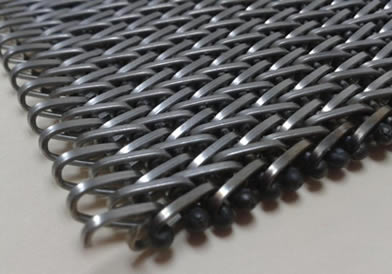

Compound Balanced Weave Belts

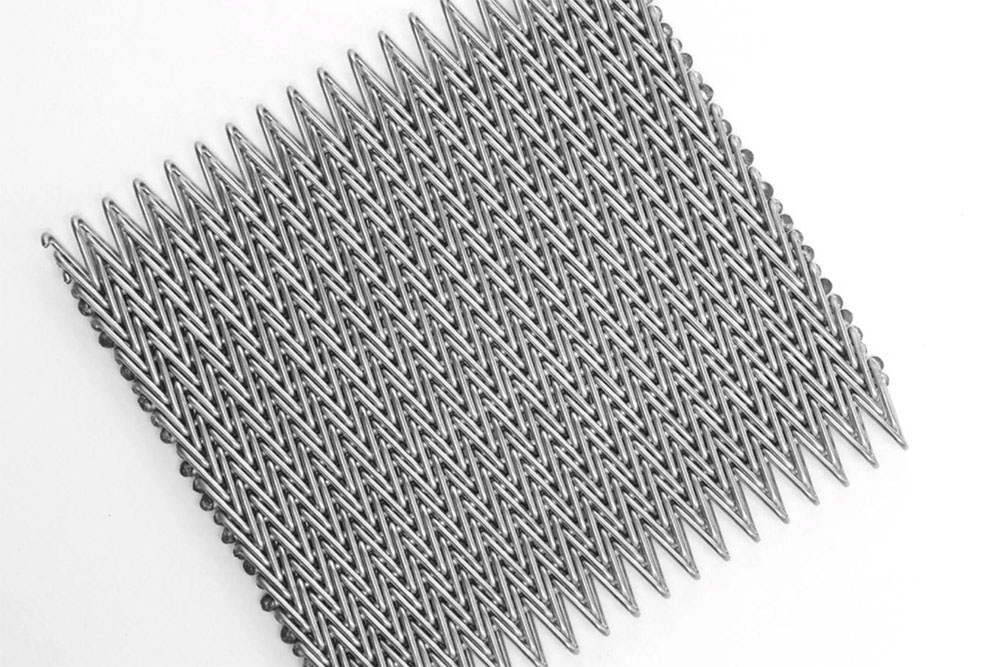

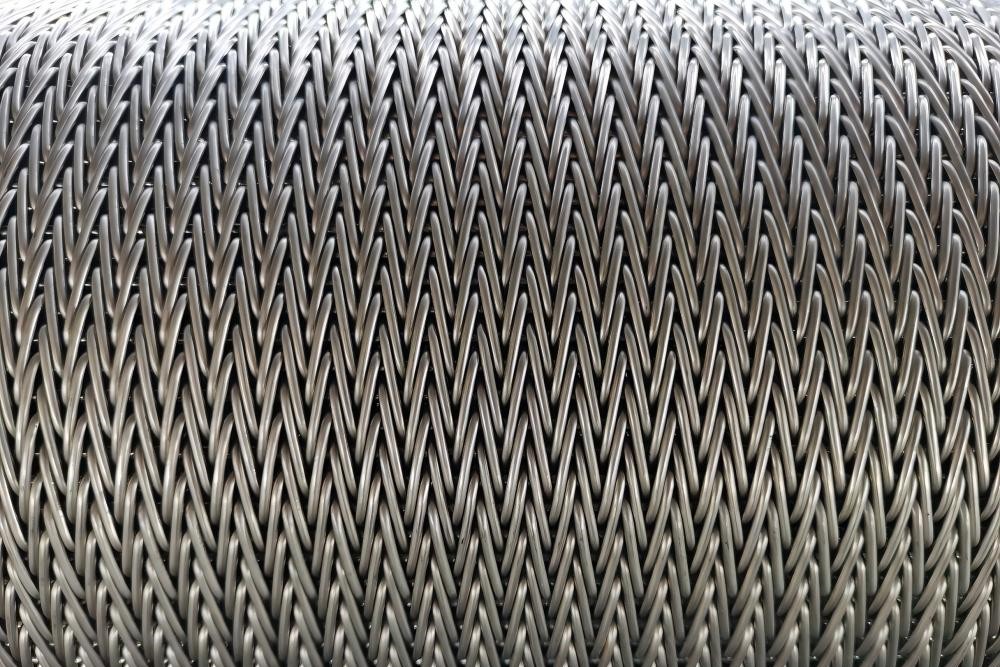

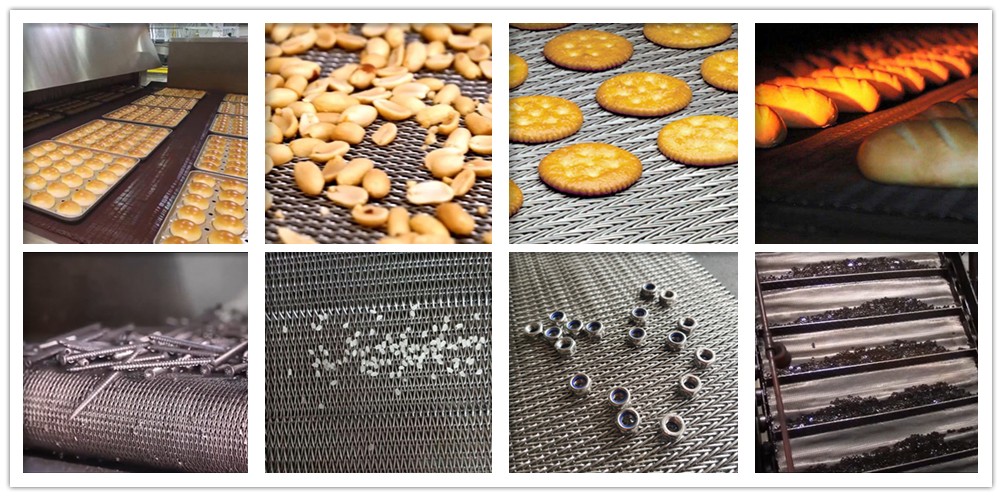

Compound balanced weave conveyor belts, also named cordweave belts or v-shaped conveyor belt, is a type of the bilateral spiral structure belt’s variant, the compact and flat wire mesh is formed with left and right spirals. The conveyor belts usually use straight rods, but the crimped cross rod can also be used in some specifications. Compared With balanced or universal weave belts, Cordweave belts offer an tighter and smoother mesh for applications where very small products and top heavy loads are being conveyed, such as nuts, biscuits, cookies, screws, bolts, nails, chemical particles, etc. Cordweave also provides a uniform heat transfer across the belt due to its high density and smooth carrying surface. These characteristics make Cordweave a popular choice in a wide variety of applications, ranging from biscuit baking to sorting small mechanical components.

|

|

Advantages

① High density construction and small open area, which is suitable to convey very small items.

② Flat smooth carrying surface, minimize marks and provide easy accurate conveying.③ Uniform heating. High density construction ensures a uniform heat transfer through to the product.

④ High-temperature resistance. The compound weave conveyor belt is made of high-quality materials, including stainless steel and nickel alloy steel, which have excellent temperature resistance performance.

⑤ Use multiple environments. High resistance against acid, alkaline, chemical, abrasion, and corrosion.

⑥ High tensile strength. The compound weave conveyor belt has multiple spirals and cross rods on each pitch, so it can supply higher tensile strength than other types of conveyor belt.

⑦ Durable and long service life. The unique structure and high-quality material can ensure the long service life of compound conveyor belt

Applications

Compound weave belting's tightly woven structure makes it ideal for baking, conveying small, unstable products and top heavy loads, such as nuts, biscuits, cookies, screws, bolts, nails, chemical particles, etc. It has been proven the highest quality baking band for biscuit and snack food.

|

① Transport ② Cooking ③ Heating ④ Cleaning ⑤ Drying (Seed) ⑥ Cooling ⑦ Freezing and salting. ⑧ Baking (Biscuits, tortillas, cookies and crackers) ⑨ Annealing (Bottle) ⑩ Elevating |

⑪ De-Elevating ⑫ Rice Handling ⑬ Swarf Conveyors ⑭ Heat Treating of Small Fasteners ⑮ Furnace Curtain ⑯ Sintering of Powdered Metal Components ⑰ Hardening, tempering, quenching. ⑱ Electro-Plating ⑲ Glass works, electrotechnical industry. ⑳ Serving as pasteurizing belt, furnace belts etc. |

Materials Available

Generally, the material used to make the Compound Weave Conveyor Belts is stainless steel or high carbon steel, other materials are available upon request. Compound weave conveyor belts made from 304 and 316 stainless steel are typically used in the food industry due to their hygienic properties, while those made from 310S and 314 stainless steel are preferred in powder metallurgy furnaces, heat treatment industry for their high temperature resistance, strong oxidation resistance and excellent mechanical properties. These belts resist short cycles, peeling, and fractures, and can withstand temperatures up to 1000-1200°C.

|

Material |

Maximum Wire Operating Temperature °C |

|

Carbon Steel (40/45) |

550 |

|

Galvanized Mild Steel |

400 |

|

Chrome Molybdenum (3% Chrome) |

700 |

|

304 Stainless Steel (1.4301) |

750 |

|

321 Stainless Steel (1.4541) |

750 |

|

316 Stainless Steel (1.4401) |

800 |

|

316L Stainless Steel (1.4404) |

800 |

|

314 Stainless Steel (1.4841) |

1120 |

|

37/18 Nickel Chrome (1.4864) |

1120 |

|

80/20 Nickel Chrome (2.4869) |

1150 |

|

310S Stainless Steel (1.4845) |

1150 |

|

Inconel 600 (2.4816) |

1150 |

|

Inconel 601 (2.4851) |

1150 |

Specifications

|

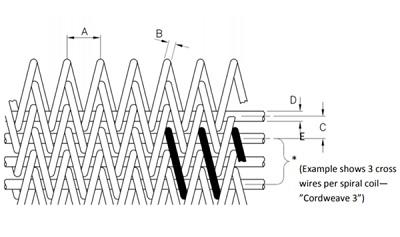

A: Coil Pitch (mm) B: Coil Wire Diameter (mm) C: Cross Wire Pitch (mm) D: Cross Wire Diameter (mm) E: Number of Cross Wires per Spiral Coil (mm) |

|

Specifications of Compound Weave Conveyor Belts |

|||||

|

Item |

Coil pitch |

Coil wire diameter |

Cross wire pitch |

Cross wire diameter |

Number of cross wires per |

|

CWCB-01 |

5.08 |

1.22 |

3.05 |

1.22 |

3 |

|

CWCB-02 |

11.29 |

2.03 |

4.35 |

2.03 |

4 |

|

CWCB-03 |

10.16 |

2.03 |

5.08 |

2.64 |

4 |

|

CWCB-04 |

4.24 |

0.91 |

2.24 |

1.22 |

4 |

|

CWCB-05 |

8.47 |

1.63 |

3.63 |

1.63 |

4 |

|

CWCB-06 |

6.35 |

1.22 |

2.82 |

1.22 |

4 |

|

CWCB-07 |

8.71 |

1.6 × 1.3 |

3.9 |

1.63 |

5 |

|

NOTE: 1. If flat wire, please give us cross section. |

|||||

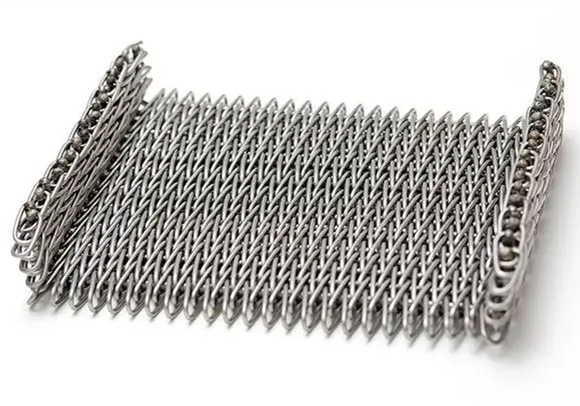

Belt Types

Compound weave conveyor belts are available in round spiral wire and flat spiral wire as your requirements:

|

|

|

CWCB01-Round spiral wire compound weave conveyor belt |

CWCB02-Flat spiral wire compound weave conveyor belt |

|

In this format both coil and cross wires are of round section. |

In this format both coil and cross wires are of flat section.

These styles are most useful to gain more surface area when handling small base area products. |

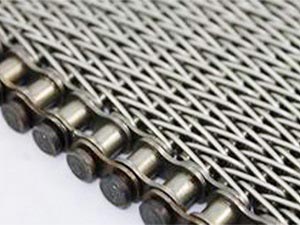

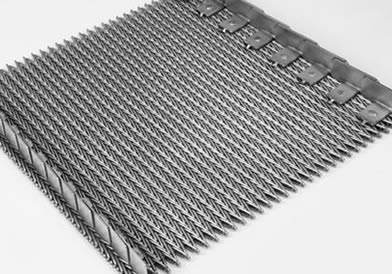

Edge Availability

For the compound weave conveyor belt, we can provide four different edge structures to meet different applications as below:

|

|

|

CWCB-03 Welded edge compound weave conveyor belt. |

CWCB-04 Chain edge compound weave conveyor belt. |

|

|

|

CWCB-05 Compound weave conveyor belt with side guard edge.----------- |

CWCB-06 Compound weave conveyor belt with folded side guard edge. |

Support & Help Info

For now, wire mesh conveyor belt is mainly divided into major categories: Chain Driven Mesh Belt is widely used in spiral freezer machines; Spiral Mesh Belts are suitable for the conveying of small and high density materials; Eye Link Belt is suited to convey heavy loads and unstable or fragile products that require good support from the conveyor belt; Balanced Weave Belt is extensively applied for conveying parts of metallurgy, food processing, pharmacy, glass print, special equipments; Flat flex belt is mainly used in for quick-frozen food, fried food, sugar machine, chocolate coating with a variety of bread and pastry food baking conveyor line; Flat Wire Belt is usually used for the equipment of cooling, drying, bread production, washing, sorting and products processing, etc. In a word, according to the use environment and clients’ special requirements, we can be able to give them different type of conveyor belt.

The compound balanced weave conveyor belt is made of stainless steel and high carbon steel, they all have excellent high temperature resistance performance and high tensile strength. All these can ensure the compound weave conveyor belt be a strong, durable and high lifespan products.

For all of your conveyor belt installation, commissioning, condition monitoring, and maintenance, please rest assured to contact us today!

Hebei Risen Conveyor Belt Products Co., Ltd

Hebei Risen Conveyor Belt Products Co., Ltd