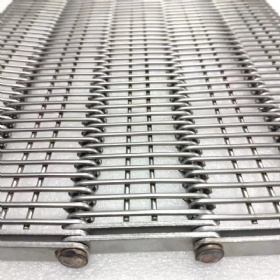

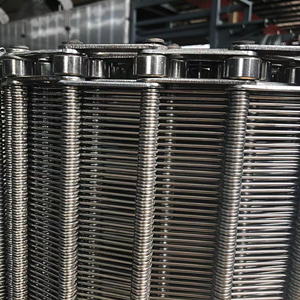

Eye Link Conveyor Belts, also named Wire Link Conveyor Belts, Eye-Flex Conveyor Belt, Wire Loop Belt. Eye link belts are produced of stainless steel or other alloys. They consist of a series of eye links or eye link modules. Joined with cross rods they form a flat, simple surface, which is extremely stable and durable. The qualities of this versatile conveyor belt form a combination of advantages that make it particularly suitable for the most demanding applications in the food, chemical, pharmaceutical and packaging industries.

Advantages

1. Enhanced Strength and Stability: Eyelink belts offer superior strength and stability due to their unique looped wire construction, ensuring reliable and consistent performance.

2. Improved Product Handling: The smooth surface of eyelink belts minimizes product damage, abrasion, or marking during transportation.

3. Flexibility: Eyelink belts can be designed with small or large openings, allowing for optimal airflow, drainage, or product separation.

4. Reduced Maintenance Costs: Easy maintenance and repair options of eyelink belts promote cost-effectiveness in the long run.

5. Customization: Eyelink belts can be tailor-made to meet specific application requirements, ensuring optimal performance and process efficiency.

Applications

Eyelink metal conveyor belts find applications in a wide range of industries, including but not limited to:

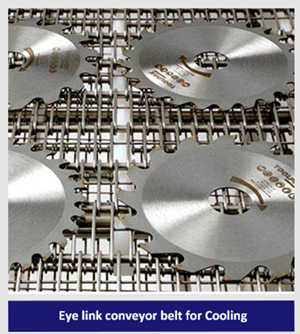

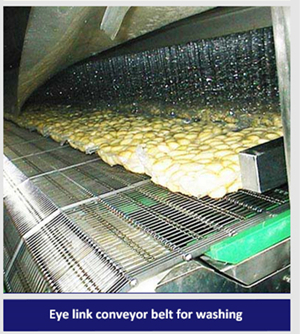

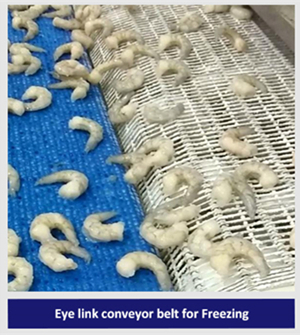

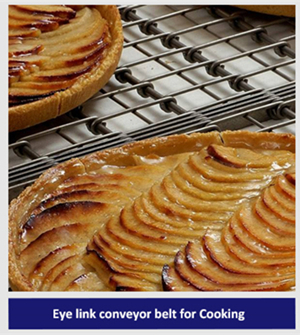

1. Food Processing: Ideal for baking, frying, cooling, freezing, washing, and drying applications.

2. Glass Manufacturing: Facilitates the transportation of fragile glass sheets or bottles during the production process.

3. Automotive: Used in automotive parts painting, cleaning, and curing processes.

4. Electronics: Suitable for circuit board production, component handling, and PCB washing processes.

5. Pharmaceutical: Enables efficient movement and processing of medicinal powders, pills, and vials.

6. Packaging: Supports efficient packaging and material handling in industries like logistics, cosmetics, and consumer goods.

Belt Types

|

|

|

ELCB01 - Eye Link Conveyor Belt without spacers |

ELCB02 - Eye Link Conveyor Belt with welded wire |

|

|

|

|

ELCB03 - Eye Link Conveyor Belt with rings as spacers |

ELCB04 - Eye Link Conveyor Belt with springs as spacers |

ELCB05 - Eye link Conveyor Belt with bushings or washers |

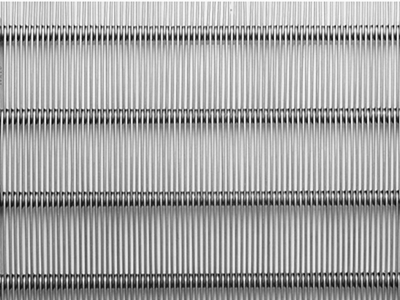

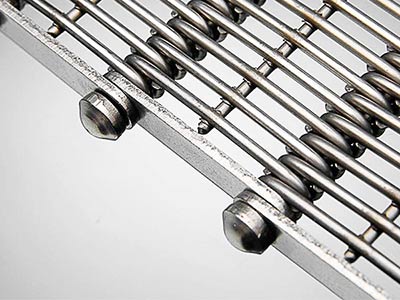

ELCB01 - Eye Link Conveyor Belt without spacers:

Eye Link Conveyor Belts without spacers are standard conveyor belts with the simplest structure based on a straight modular form without any spacers and springs, which makes it excellent flow-through in applications that do not require cross support. Eye Link Conveyor Belt has flat conveying surface and open mesh structure, which make it ease of cleaning, also easy to repair at the lowest cost.

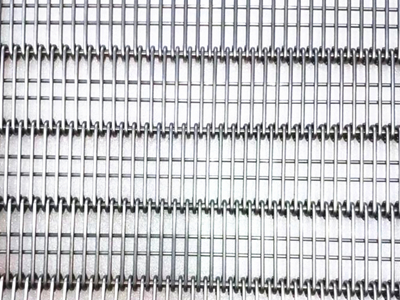

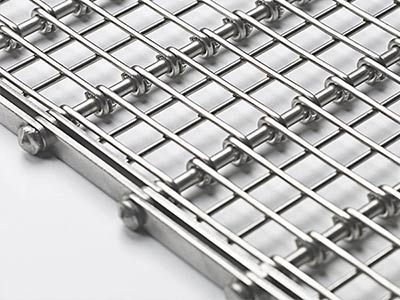

ELCB02 - Eye Link Conveyor Belt with welded wire:

Eye link belt has steel wires which was welded under the belt, this not only enhances the stability of the belt, but also prevents bacteria from being left behind due to gaps in the belt. Eye link Conveyor Belt with welded wire is very suitable for applications with high hygiene requirements, such as the processing of various meats and the cleaning and drying of vegetables and fruits.

ELCB03 - Eye Link Conveyor Belt with rings as spacers:

The conveyor belt uses rings as spacers to expand the belt gap and increase more air flow at the bottom of the conveyed product, thereby improving the working efficiency of the conveyor belt. This type of conveyor belt is commonly used for large product conveying, vegetable blanching, container pasteurization, and food cooking, baking, and cooling.

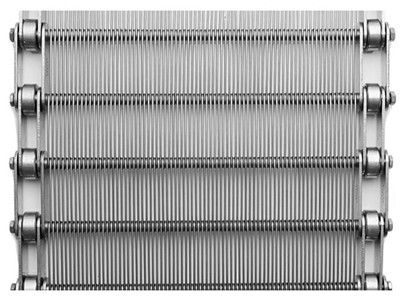

ELCB04 - Eye Link Conveyor Belt with springs as spacers:

Adding springs between eye-link wires, the springs make the eye-link wires able to move on the cross rods, which make the belt form a more dimensionally stable structure. The addition of springs increases the belt open area, which is more conducive to the cleaning and disinfection of the conveyor belt. This belt usually used for product transportation, vegetable blanching, and pasteurization of cans, bottles, and cans.

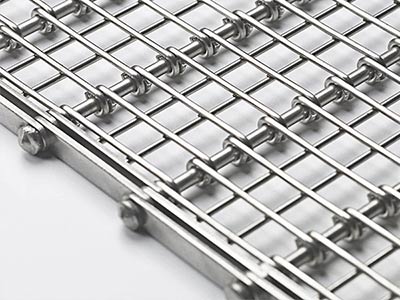

ELCB05 - Eye link Conveyor Belt with bushings or washers:

Eye link belt uses bushings or washers between the wires to increase the belt gap, create an opening between the eyelinks. By increasing the belt gap, more air will circulate around the bottom of the product. In addition, the belts become heavier and more rigid after bushings or washers are added.

Edge Types

|

|

| ELBE01 - Eyelink Belt with Welded edge |

ELBE02 - Eyelink Belt with Reinforcing Plates |

|

---------Eye link belt with welded edge is the simplest eyelink belt edge, through welding metal plates to cross rod at the edge of the wire ring conveyor belt, to form a complete conveyor belt . |

Reinforcing plates are common edge, through adding reinforcing plates mounted to the conveyor belt edge before the connecting rod is welded to further enhance the width and strength of this belt. |

|

|

|

ELBE03 - Eyelink Belt with Chain Edge |

ELBE04 - Eyelink Belt with side Guards |

|

Chain edges on Eye link belts as an alternative method for driving the belt for enhanced tracking and reliability, make the chain edge conveyor belt much stronger than reinforcing plate edge. |

Eye Link belts with side guards can efficientlly protect conveying products from falling off the side of the belt. As your request, guard plates can also be mounted across the belt for food separation. |

Materials Available

|

Material |

Maximum Wire Operating Temperature °C |

Feature |

|

Carbon Steel |

550 |

Good wearability |

|

Stainless Steel 304 |

750 |

Often used |

|

Stainless Steel 316 |

850 |

Corrosion-resistant |

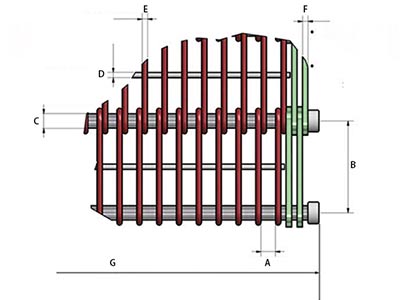

Specifications

- Material: SS 304, SS 316, carbon steel

- Wire diameter: 1.5 mm, 1.6 mm, 1.8 mm, 2 mm, 2.5 mm, 3 mm.

- Spiral pitch: 2.4 mm to 100 mm.

- Rod pitch: 25.4 mm, 31.75 mm, 38.1 mm, 50.8 mm, 63.5 mm, 76.2 mm.

- Chain pitch: 25.4 mm, 31.75 mm, 38.1 mm, 50.8 mm, 63.5 mm, 76.2 mm.

- Rod diameter: 5 mm, 6 mm, 7 mm, 8 mm, 10 mm, 12 mm.

- Belt width: 200 mm to 6,000 mm.

|

A: Gap Width (mm)

B: Pitch (mm)

C: Cross Rod Dia (mm)

D: Underside Welded Wire Dia (mm)

E: Wire Link Dia (mm) G: Overall Belt Width (mm) |

|

Table 1 - Eyelinks conveyor belt without spacers |

||||||

|

Item No. |

Belt Pitch (mm) |

Wire Dia. (mm) |

Cross Rod Dia.(mm) |

Belt Pitch (mm) |

Wire Dia. (mm) |

Cross Rod Dia.(mm) |

|

RSELCB01 |

15.875 |

1.8 |

3.2 |

50 |

3 |

5 |

|

RSELCB02 |

25 |

2 |

5 |

50.8 |

1.6 |

8 |

|

RSELCB03 |

25.4 |

2 |

5 |

50.8 |

1.6 |

6 |

|

RSELCB04 |

30 |

1.6 |

4 |

50.8 |

2 |

8 |

|

RSELCB05 |

30 |

2 |

4 |

50.8 |

2.5 |

8 |

|

RSELCB06 |

30 |

2 |

5 |

50.8 |

2.5 |

5 |

|

RSELCB07 |

30 |

2 |

7 |

50.8 |

3 |

5 |

|

RSELCB08 |

30 |

2 |

8 |

50.8 |

4 |

7 |

|

RSELCB09 |

31.75 |

2 |

5 |

60 |

2 |

5 |

|

RSELCB10 |

50 |

1.4 |

5 |

60 |

2.5 |

5 |

|

RSELCB11 |

50 |

1.6 |

5 |

70 |

4 |

7 |

|

RSELCB12 |

50 |

2 |

5 |

75 |

2.5 |

5 |

|

RSELCB13 |

50 |

2.5 |

6 |

75 |

2.5 |

8 |

|

RSELCB14 |

50 |

2.5 |

8 |

100 |

3 |

8 |

|

Table 2 - Eye link conveyor belt with under welded wire spacing |

||||||

|

Item No. |

Belt Pitch |

Wire Diameter |

Cross Rod Diameter |

Minimum Gap |

Gap in Steps of |

Maximum No. of Welded Wires(mm) |

|

RSECBWS01 |

15.875 |

1.8 |

3.2 |

2 |

0.1 |

1 |

|

RSECBWS02 |

25 |

2 |

5 |

2.3 |

0.1 |

2 |

|

RSECBWS03 |

25.4 |

2 |

5 |

2.3 |

0.1 |

2 |

|

RSECBWS04 |

30 |

2 |

4 |

2.3 |

0.1 |

2 |

|

RSECBWS05 |

30 |

2 |

5 |

2.3 |

0.1 |

2 |

|

RSECBWS06 |

50 |

2 |

5 |

2.3 |

0.1 |

3 |

|

RSECBWS07 |

50 |

2.5 |

5 |

2.8 |

0.1 |

3 |

|

RSECBWS08 |

50 |

2.5 |

6 |

2.8 |

0.1 |

3 |

|

RSECBWS09 |

50.8 |

2.5 |

8 |

2.8 |

0.1 |

3 |

|

RSECBWS10 |

50.8 |

3 |

8 |

3.3 |

0.1 |

3 |

|

RSECBWS11 |

75 |

2.5 |

5 |

2.8 |

0.1 |

3 |

|

RSECBWS12 |

75 |

2.5 |

8 |

2.8 |

0.1 |

3 |

|

Table 3 - Eye link conveyor belt with rings as spacers |

|||||

|

Item No. |

Belt Pitch (mm) |

Wire Diameter (mm) |

Cross Rod Diameter (mm) |

Minimum Gap Spacing (mm) |

Gap Spacing can be |

|

RSECBWR01 |

25 |

2 |

5 |

4 |

2 |

|

RSECBWR02 |

25.4 |

2 |

5 |

4 |

2 |

|

RSECBWR03 |

30 |

2 |

4 |

4 |

2 |

|

RSECBWR04 |

30 |

2 |

5 |

4 |

2 |

|

RSECBWR05 |

31.75 |

2 |

5 |

4 |

2 |

|

RSECBWR06 |

50 |

2 |

5 |

4 |

2 |

|

RSECBWR07 |

50 |

2.5 |

5 |

5 |

2.5 |

|

RSECBWR08 |

50 |

2.5 |

6 |

5 |

2.5 |

|

RSECBWR09 |

50.8 |

2.5 |

6 |

5 |

2.5 |

|

RSECBWR10 |

50.8 |

2.5 |

8 |

5 |

2.5 |

|

RSECBWR11 |

50.8 |

4 |

8 |

8 |

4 |

|

RSECBWR12 |

60 |

2 |

5 |

4 |

2 |

|

RSECBWR13 |

60 |

2.5 |

5 |

5 |

2.5 |

|

RSECBWR14 |

75 |

2.5 |

5 |

5 |

2.5 |

|

RSECBWR15 |

75 |

2.5 |

8 |

5 |

2.5 |

|

Table 4 - Eye link conveyor belt with springs as spacers |

||||||||||

|

Item No. |

Belt Pitch |

Wire Diameter |

Cross Rod Diameter |

Minimum Gap Spacing |

Gap Spacing also Available in these Widths (mm) |

|||||

|

RSECBWS01 |

25 |

2 |

5 |

7 |

8 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS02 |

25.4 |

2 |

5 |

7 |

8 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS03 |

30 |

2 |

4 |

7 |

8 |

10 |

12 |

- |

- |

20 |

|

RSECBWS04 |

30 |

2 |

5 |

7 |

8 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS05 |

31.75 |

2 |

5 |

7 |

8 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS06 |

50 |

2 |

5 |

7 |

8 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS07 |

50 |

2.5 |

5 |

7.5 |

8 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS08 |

50 |

2.5 |

6 |

7.5 |

- |

- |

- |

- |

- |

20 |

|

RSECBWS09 |

50 |

3 |

8 |

10.5 |

- |

- |

- |

15.5 |

- |

20 |

|

RSECBWS10 |

50.8 |

2 |

6 |

7 |

- |

- |

- |

- |

- |

- |

|

RSECBWS11 |

50.8 |

2 |

8 |

8 |

- |

- |

- |

- |

- |

- |

|

RSECBWS12 |

50.8 |

2.5 |

6 |

7.5 |

- |

- |

- |

- |

- |

20 |

|

RSECBWS13 |

50.8 |

2.5 |

8 |

10 |

- |

- |

- |

15 |

- |

20 |

|

RSECBWS14 |

50.8 |

3 |

8 |

10.5 |

- |

- |

- |

15.5 |

- |

20 |

|

RSECBWS15 |

50.8 |

4 |

8 |

12 |

- |

- |

- |

- |

- |

- |

|

RSECBWS16 |

60 |

2.5 |

5 |

7 |

8 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS17 |

60 |

2.5 |

5 |

7.5 |

8.5 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS18 |

70 |

4 |

7 |

12 |

- |

- |

- |

- |

- |

- |

|

RSECBWS19 |

75 |

2.5 |

5 |

7.5 |

8.5 |

10 |

12 |

15 |

17.5 |

20 |

|

RSECBWS20 |

75 |

2.5 |

8 |

10 |

- |

10 |

- |

15 |

- |

20 |

|

RSECBWS21 |

100 |

3 |

8 |

10.5 |

- |

10.5 |

- |

15.5 |

- |

20 |

Potential Issues & Solutions

2. Product Sticking: Certain materials may stick to the belt surface, impeding the conveying process. Introducing a release agent or opting for a Teflon coating can mitigate sticking issues.

3. Belt Wear and Tear: Regular cleaning, monitoring and replacing damaged links or coatings can prevent excessive wear and prolong belt's lifespan.

4. Belt Cleaning: For applications requiring regular cleaning, incorporating a cleaning system along the belt path or using modular belt designs with removable links can simplify maintenance.

In conclusion, eyelink metal conveyor belts offer a versatile and effective solution for a wide range of industries. With their durable construction, customizable design, and superior performance, they outperform traditional metal mesh belts in various applications. Understanding potential challenges and implementing appropriate preventive measures ensures the smooth operation and longevity of eyelink metal conveyor belts.

Hebei Risen Conveyor Belt Products Co., Ltd

Hebei Risen Conveyor Belt Products Co., Ltd